How to ensure that the test data of the brake system of electric scooters is accurate and reliable?

How to ensure that the test data of the brake system of electric scooters is accurate and reliable?

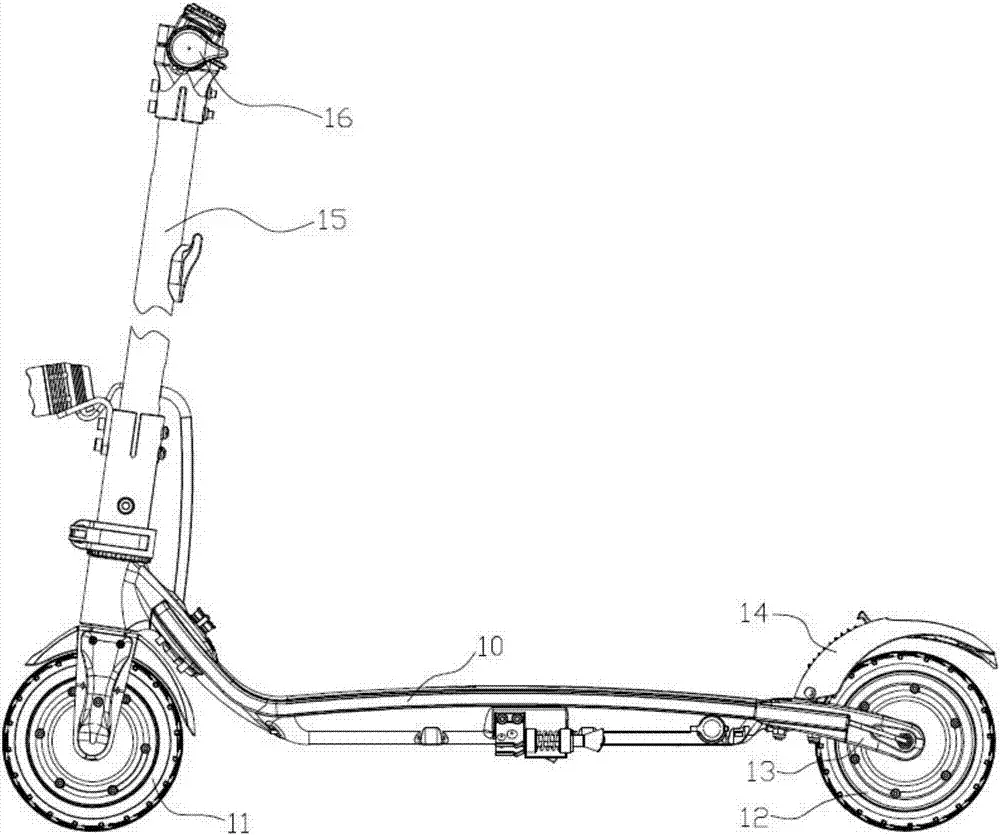

At a time when the electric scooter market is booming, the reliability of the brake system, as a core component related to riding safety, has attracted much attention. For electric scooter manufacturers and suppliers committed to developing the international market, providing accurate and reliable brake system test data is not only the key to meeting the stringent standards of overseas wholesale buyers, but also an important cornerstone for enhancing brand competitiveness and winning global market share.

1. Follow authoritative test standards to lay the foundation for data reliability

Internationally, there are a series of strict standards and specifications for the brake system testing of electric scooters. For example, the EU's EN15194 standard has detailed provisions for the braking performance of electric scooters in terms of test speed, braking distance, braking stability, etc. The US UL2272 standard also puts forward clear requirements for the safety of the electrical system and braking system of electric scooters. When manufacturers conduct brake system tests, they must strictly follow these standards to ensure the standardization of the test process. This means that from the selection of test equipment, the construction of the test environment, to the execution of test steps, they must accurately benchmark international standards to make the test data authoritative and credible from the source.

2. Use high-precision test equipment to ensure data collection accuracy

Accurate test equipment is the prerequisite for obtaining reliable data. In the test of the electric scooter brake system, a professional braking distance tester can accurately measure the braking distance of the vehicle at different speeds, and the error range is controlled within a very small range. At the same time, it is equipped with a high-precision pressure sensor to monitor the pressure value applied to the brake system by the brake handle or brake pedal in real time to ensure that subtle changes in the data can be accurately captured. In addition, a high-speed camera is used to record the braking process, and every moment from the start of braking to complete stillness of the vehicle can be clearly presented, providing an intuitive and detailed visual basis for subsequent data analysis.

3. Strictly control the test environment variables to reduce data deviation interference

The test environment has a significant impact on the performance of the brake system. In terms of temperature, extreme high or low temperatures may affect the material properties of the brake components, thereby changing the braking effect. Therefore, when testing, it is necessary to conduct the test within the standard temperature range, record the specific temperature value, and analyze its impact trend on the data. Humidity should not be ignored either. Slippery roads will reduce the friction between the tire and the ground and increase the braking distance. Therefore, the test should be carried out under the specified humidity conditions, and the braking performance under different humidity conditions should be compared to fully evaluate the adaptability of the system. The road condition is even more critical. A flat, dry road with a friction coefficient that meets the standard is an ideal choice. At the same time, it is necessary to ensure that the road conditions are consistent for each test to avoid data fluctuations due to differences in the road surface.

4. Improve the professional quality of testers and ensure the standardized implementation of the test process

A professional testing team is the core force for obtaining accurate data. Testers need to receive systematic training, deeply understand the structural principles of the electric scooter braking system, master the operating skills of various test equipment, and be familiar with every detail of the international testing standards. In actual testing, the standard process should be strictly followed, from the initial state setting of the vehicle, to the data recording during the test, and then to the data collation and analysis after the test. Every link must be rigorous and meticulous. In addition, team members should have good collaboration skills and be able to cooperate efficiently in complex test projects involving multiple people to ensure the continuity and accuracy of the test.

5. Use scientific data recording and analysis methods to tap into the deep value of data

In terms of data recording, professional data acquisition software is used to record various parameters of the brake system during the test in real time and continuously, such as brake pressure, deceleration, braking distance, etc., to ensure the integrity and continuity of the data. For the recorded data, advanced data analysis tools and algorithms are used for processing. For example, through statistical analysis methods, the average value, standard deviation, etc. of the data of multiple tests are calculated to evaluate the central trend and dispersion of the data, so as to judge the performance stability of the brake system. At the same time, with the help of data visualization technology, complex data is presented in the form of intuitive charts, such as the relationship curve between braking distance and speed, and the comparison bar chart of data under different test conditions, etc., to help testers and management have a clearer insight into the performance characteristics of the brake system and provide a strong basis for product optimization and upgrading.

6. Carry out comparative testing and third-party certification to enhance data credibility and market competitiveness

Comparative testing with similar competing products is an effective way to demonstrate the advantages of the brake system of one's own products. Under the same test conditions, the braking performance of electric scooters of different brands is compared horizontally, and evaluated from multiple dimensions such as braking distance, braking stability, and noise level, to intuitively present the competitiveness of the product. In addition, third-party authoritative certification agencies, such as SGS and TUV, are introduced to audit and certify the brake system test data. These agencies, with their professional technical teams and strict audit processes, endorse the accuracy and reliability of the data, making the products more convincing in the international market, helping to successfully pass the qualification review of overseas wholesale buyers, and enhancing the brand's global recognition and reputation.

7. Continuous improvement and innovation to promote the performance of the brake system to a new height

The electric scooter industry is constantly developing, and technology is updated and iterated rapidly. Manufacturers should pay close attention to industry trends, actively invest in research and development resources, and continuously improve and innovate the brake system. For example, explore the application of new brake materials to improve the wear resistance, heat dissipation and braking performance of brake components; study intelligent brake assist systems, monitor road conditions and riders' braking intentions in real time through sensors and algorithms, adjust the braking force in advance, and achieve more accurate and safer braking effects. At the same time, based on big data analysis, we collect feedback data on brake systems in actual use in the market, compare and analyze them with laboratory test data, find potential problems and improvement directions, and continuously optimize product design to make the brake system more reliable and durable in actual applications, so as to always maintain a leading position in the fierce international market competition.

In short, ensuring the accuracy and reliability of electric scooter brake system test data is a systematic project, which requires starting from test standards, equipment, environment, personnel, data processing, comparative certification and continuous innovation, and creating a high-quality test system in all aspects. This not only helps to meet the strict requirements of international wholesale buyers for product safety and performance, and enhance the competitiveness of products in the international market, but also reflects the responsibility for consumer life safety, and lays a solid foundation for the healthy and sustainable development of the electric scooter industry.